|

|

www.coilgun.ru |

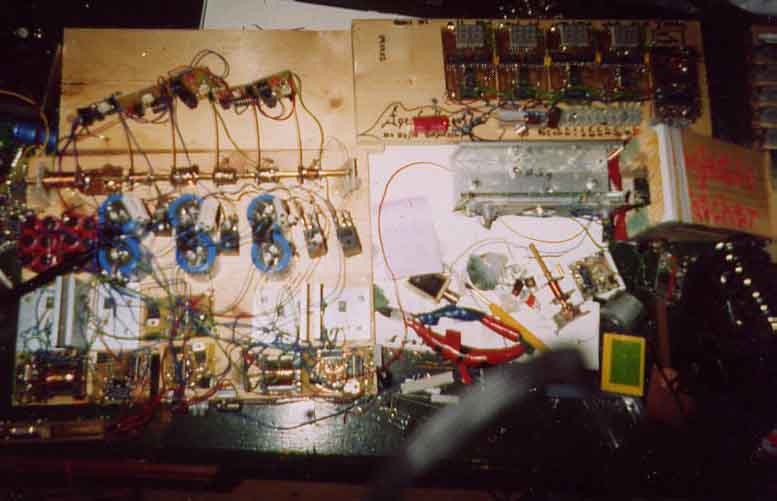

The picture is my new, number 2 coilgun. It is driven by an battery pack (not mounted yet) with 10-12 'discman-size' LiMH rechargeable batteries. This gives me about 12 volts in serial. This in turn is by means of a transformer stepped up to 400 volts, loading a bank of capacitors. This process is fully 'automatical', a voltage detecting system turns this charging system on when voltage is less than 380 volts. Then, to fire it, you must lift a small tube-thing with a back-drawing spring attatched. Put the projectile in and let the spring pull it back into correct position, right infront of the barrel. Between the barrel and projectile now is only a blocking device preventing the projectile from slipping into the barrel. Now that the gun is loaded and the charging is complete...Fire!

To do so, just aim and pull the trigger just like any ordinary gun. This is what will happend:

The trigger signal is cleaned and is merely used to turn on an latching system, so no incomplete or trigger debounching might occur. The controlling circuits then first turn on the IR LEDS and almost the same time the sensors, a very low delay to prevent the sensors to false trigger due to low IR. 1/10 seconds later, the blocking device is magnetically removed to open the barrel for the projectile. 1/3 seconds later, a powerful solenoid behind the projectile is turned on, kicking the projectile hard and fast into the barrel. And ofcourse, now it accelerates very fast due to the coils. At last, 1,5 seconds after triggering, all the systems are turned off and a new cycle may begin.

Because you found this page, it is likely that you already know somewhat of coilguns or other electro-driven weapons. Yes, I say weapons and not 'science projects'. First, because it is both, we already know you must research and think alot to build a fairly working device, so that it is science we already know. And besides. I am just a boy/man whatever you judge my 22 years. And all boys I know reacts some special way when it comes to guns, weapons, scary looking science devices, big explotions and so on. And I know all they really want to build is powerful weapons, just disguised as science-projects which 'justifies' the construciton in a political correct way. I am not any worse than others, I just realize this and from now on, it is coilGuns.

The way from scratch, theoretically calculations if any, schematics, and components, is long. If you don't have done this bit yet, the description of my guns infrastructure is of no value now. It is what I call the 'cozy works'. Because you now know the main thing works, and the last can be very simple and still work, it does not include huge amounts of power, and can be done to function very cool. It is the main gun, just the barrel, the coil, the switch, the capacitor and triggering device who people fail on, when building these.

When you decide to build one, you probably have no idea of just how much work there can be. It is almost like a law, there will always be unexpected problems you never dreamed of, and who, according to your perfect schematic, can't be there. But, to add some deciding problems first when the idea has come. What kind of coilgun? A small and compact hand-held? A powerful? A very fast? A gun with high efficience? A cheap? An easy? A gun from the scratch I already possess? A gun derived from first heavy calculations, or use the more non-mathematical way, the evolution procedure, make three and only develope the best after test). All?

Well...first let's define coilgun. It is a device witch accelerates a projectile by means of electromagnetic coil through a barrel. This I do, so I don't have to include Thomson-coils, disc-shooters, rail-guns and other such. Why then choose coilgun to build? Easy, because it has a, compared to the other devices listed, a high efficience, it can run on moderate low voltage and powers (not lethal as the others), the energy-transfer from the coils to the projectile can be done by several coils, instead of just one big pulse as the others, it doesn't usually utilize parts who are beeing destroyed after some time (the rails and projectile in railgun, the spark-gap switch), and even the projectile in the coilgun is usually a solid piece of metal and isn't destroyed (unless very high velocity) and can be used many times, which is very valuable when tuning the coilgun, which means a lot of firing. To do this with a, say disc-shooter, would be very difficult. The disc will be destroyed or will be damaged after some time. This is very not wanted. Why? Because it is boring to make a hundred projectiles, and more important, when you tune your gun to see what makes the projectile go faster, you must of course use the same projectile as last time! As you understand, a test must be performed with the same stuff in the same state as last, how could you else know if the gain or loss in test was due to new parameters or new state of the tested thing?

So, enough 'why-to-choose-coilguns'. Now the first question as asked above. What kind of coilgun? Of couse, you want it hand-held, with high efficence, cool to look at, both high velocity and high power, high rounds-per-minute and so on. But as you guess, all this at the same time is simply not possible, at least not with exsisting coilgun-technologi which I am aware of. You should probably decide one or two as main goals. But just as in my case, the descition is usually made by the components I have or can obtain. Therefore, my two coilguns is made with not so much thought of the 'main goal', but more derived from the best I can achieve with the components. But if you are to obtain all components new, and have lot to choose between, it is more practial to choose components with thought of the desired goal.

First, a quick explanation on how the coil works. On the first picture, you se the barrel, the coil (cut in half) and the white projectile. Now, what happens if we connect a power source at the coil terminals? The projectile is drawn into the coil! And as long as it is energized (and the coil acts as a magnet), the projectile will stop and stay in the middle. It will not shoot out on the other side, because the magnetic field the coil creates, draws the projectile as near as possible itself (the middle), just as a ordinary magnet. But what if you could turn the magnet off, just when the projectile had reached the middle? The coil wouldn't draw it any more, and no magnetic powers would stop it from just continuing out the other side. And the stronger magnetic field, the more powerful the coils magnetic powers will be, and it will draw the projectile inn faster with more power. This is the coilgun. It is more advanced than this, but on the easy versions, it doesn't have to be.

POWER SWITCHING ASPECTS

So, what happens more advanced? The problem is that a coil is a inductive device. When energizing the coil, it will resist the flow of electricity first, before the full amount of power can run through it. Just like a choke kills pulses. It takes a certain amount of time to establish the magnetic field (the rise of it is what resists full power at first). In slow coilguns this isn't usually a problem, because the projectile never reaches the velocity required for this to become a problem. But at higher velocity, we must try to minimize this problem. The only thing I know done is very linear easy. The higher voltage, the faster the magnetic field establises, and full power can run. Therefore, almost all fast powerful coilguns use high voltages. (300-1500 volts is usually high for coilguns, and most used). The next problem that occurs, happends when we turn the energy off. Where does the magnetic field go? As you know, a transformer makes magnetic fields at the first coil that collapse as energy into the second coil. Here, we have no second coil. So the energy just collapses into the coil itself as electric energi. But the circuit is open! It has just been stopped to prevent the projectile to be sucked back into the coil. So the energy induced back can not flow. This is the problem, because then the voltage in the coil (the pressure!) will rise and rise until it is in theroy very very high. And suddenly, poff, the high voltage of many kilovolts destroys the device that switches the power on and off. How to prevent this? We can't place a second coil nearby to hope the power is induced into this instead, because we need the magnetic energy to act on the coil, not beeing induced into a second useless coil. Besides, it probably wount't dispatch all the energy. The second thing we could do, is linear easy. Use lower voltage in coil to prevent an all-to high voltage spike returned, and lower power wouldn't produce so intense magnetic field and hence intense return-spike. Third, you could use a lower number of windings in coil. Smaller coil means smaller inductance and hence lower spike. Forth, you can wind the coil with smaller diametre of wire. Smaller wire is less inductive than thicker wire.

Usually a combination of these is applied to prevent the most extreme spikes, but the real spike-killers isn't in these design procedures. Therefore we have several electrical means of preventing this. The first, most used, is to connect a diode in parallell with the coil. The diode does as known only allow current to pass through one way. When we know the spike generated will always have the opposite voltage than the coil was applied with, it is an easy thing to do - the diode will not lead current through when power turned on, if placed opposite way. But however, when the spike occurs after turn-off, it is opposite, and for this voltage, the diode is placed in the right way. It simply short it out. This is a good thing in lower-power guns. But the diode has a certain delay before it can conduct, and if a high intense magnetic field is collapsing, it might have developed to a destructive spike before the diode shorts it out, and therefore destroys the switch or the power source. You could buy fast-diodes, transient-diodes specially made for this, and these are a good choice. A problem will just the same occur in high-power designs. The magnetic field might be so intense, that when the diode is shorting the induced energy, it is beein destroyed due to internal overheating. Obvious solutions are to buy higher-power versions or to parallell more of them. Parallelling might work to some degree, however, one diode will always differ very minor from another, possible start conduction before the other does, destroying this. But all the same, if it is not so much more intense spike that one could handle, parallelling should prove a good way. The next way is very effective, bur requires that you use a relative high voltage. In parallell with the coil, place a spark-gap (solid state small versions sold as transient-protection, ranging from 100 volts and upwards) with slightly higher voltage breakdown than the capacitor charge. And use a switching device that can handle a voltage even higher than this. Then when the transient occurs, it builds up and the spark-gap triggers it completely dead, long before the voltage reaches the even-higher switch max voltage. Another way to kill it is even simpler. Use a switch that cannot be turned off again after triggering. But wait, you say, wouldn't that produce suck-back of projectile? Yes, it would, but if the energy source is emptied before the projectile has reached the middle, there would be no energy left to do this. As the voltage in the source drops while discharging, the magnetic field will be weaker and weaker, and not produce a spike since this is done over some time.The conditions the coil requires to produce a spike isn't there! And now the last method. The simplest in theory. Don't use a switch destructible by a spike. A light-bulb switch. A relay. With these, the only possible destruction is the power-source. But the have a very big drawback. They can't be fast enough switched, and the terminals inside will probably be welded together when closing. This method is therefore only used in low-power single-coil configuration where we utilize a powersource who will be emptied before the projectile reaches the middle.

SWITCHING

Now some information on the switching methods. I have already covered the mechanical switches such as ligh-bulb and relay. So for serious coilgunners, there must be utilized a switching method which is: Fast to trigger electrically and have big peak power handling. And as a last word, the switch is really all that in normal design limit your power.

First device is the bipolar transistor. It it usually slow to trigger, the power-versions needed require huge amounts of trigger-current, and in general they are pretty weak devices compared to the others. But they could be used on small guns.

Second device is the MOS-FET. It works like the transistor, but it is voltage-controlled rather than current-controlled as the transistor. So we don't need a lot of continoous current to trigger it, just one big pulse to turn it on fast and then very very little power. They can withstand much more current in general. Drawback is that they can't stand all to much current, and are easely destroyed by the spike because they are static sensitive.

Third is the IGBT. As I have understood the device, it is a voltage-controlled transistor. Trigger it just as a mosfet, and they can withstand more power than the transistor. They are expensive, but good.

The forth is, in my eyes, the best one yet. The Thyristor or SCR. It can turn on huge amounts of energy, far more than any of the others, and they are very fast to trigger. So what drawback? They can't be turned off, once they have been triggered! The only thing that can turn them off, is a voltage drop across it under a certain treshold limit. This resets the device to the 'off-state'. To use them, special contructions must me made, but the huge power-transfer justifies this.

Fifth, is the more experimental switches. First, a kind of spark-gap switch. They work very well on single-coil guns due to theyr very very high current transfer ability, even with a loss of maybe 30% energy. But they are expensive and probably very hard to come by. How accurant you can trigger them, is also unknown by me. But they can be home-made, since the princip is easy enough. Actually, once, when I first started thinking of coilguns, I planned to use xenon flash tubes as switches! The biggest problem with these devices as stated, is reliable triggering, and also that they are gradually beeing destroyed when used. But often I find myselv thinking very hard on how to utilize the tremendous power the spark-gap can transfer. But obvious not for a hand-held device, since they are big and bulky. As a last warning on these, they requires often far mor than 1000 volts to function, maybe several 10's of kilovolts to be reliable. And I don't have that kind of capacitors to play with. Not to mention these would be absolutely lethal.

POWERSOURCES

And now, what power-sources? They must deliver very much current very fast, have high or desired capacitance and a small volume. And they should be able to withstand high voltages, and have small leaks.

Car battery. Can in single-pulse probably deliver several hundres of amperes, specially when parallell-coupled with more. But, it is only 12 - 16 volts in them! Very hard to use so low voltage, and the total wattage of energy put out, isn't so much.

Capacitors. I can't remember any real coilgundesign not using these. Why is obvious. They are small, easy to use, can deliver an almost unlimited current spike and can easily be obtained by everyone in many forms and types. This is, if you are not planning a very high rounds-per-minute low power coilgun, the only realistic choice.

It exsist some other devices too, but they are not accessible for us hobby-gunners. And they are often very big, including very fast spinning heavy metal parts, very big power consumption. Not realistic for me to use. And what is really wrong with capacitors? As said before, usually the problems and limits with coilguns occur with the switch.

METHODS TO UTILIZE THE CAPACITOR ENERGY

Single Caps, Single Coils. What I here mean, is that one capacitor is connected to one coil. When the power is drained from the cap, it will be impossible to activate the coil again since there are no more energy left. You have to charge it up again. Why is this good? All the coils can perform max peak power, since they all have theyr'e own designated capacitor, not shared by any else. And it is nescessary when using switches that cannot be turned off. As said, in these, the power must be drained very fast, before the projectile reaches the middle. Why is coil with designated capacitors bad? They must be somehow insulated from each other to prevent that a voltage-drop in one (the coil discharge), suddenly drains power from another full. At the same time, they must be charged simoltanious. This can be problematic, especially in high-voltage design. Another minor problem is measuring voltage. Only one capacitor can be measured at the same time, and this has a tendency to leak faster than the others, resulting in a recharge-command from the charger system, when there is only one needing it. This might overcharge the others.

Capacitor bank. All the capacitors are coupled together as one. One coil does not drain all the energy, and it is left energy to the next, and the next etc. This is good because it is easy to make this arrangement, and easy to monitor the voltage-leaking, since they are as one. And if you have a very high capacitance, you could even make a multi-shot device, shooting maybe three times before the power has been too much drained. And here lays the problem. It will be lower and lower energy available to the coils, resulting in a lower and lower energy-transfer to projectile. So even if more easy, in my experience less effective, and you couldn't use thyristors on this device, you have to use a switch that can be turned off like MOS-FETS, thus limiting the amperes to flow since MOSFETS in general can't handle so much energy as thyristors.

HOW TO TRIGGER THE SWITCH?

The first I know, is the most commonly used. The optical trigger. The only bad thing with it, is that it requires a line of free sight through the barrel, right infront of the coil it shall trigger. This means, unless you use a opaque barrel, drilling holes is nescessary. You should drill nice small holes. Then it it just a question of mounting a light emitting diode (LED), and at the other side mount a light dependant diode or a light dependant transistor. The transistor is cheaper and more easy to use, since there is a big span in resistance between full light and no light. The diode is more expensive, needs more sensitive circuits since there is a lower resistance-span, but faster. So in high-velocity guns you might need them for optimum performance. In almost all design, you will see they use IR leds instead of visible-light diodes. This is done because the light dependant device is usually much more sensistive to IR than to visible light.

The second used is usually much more complex. You wind a small coil in front of the coil you want to activate. The projectile will induce a small current in this coil when moving throught it, and using this current you could trigger the switch to the main coil. And you don't need holes throught your barrel. Then the bad thing. How are you going to prevent the coil from not trigger on induced current from the other coils? You would need either much filtering, or logical selection of pulses. Me myself have never used this method, mainly because I like the 'simple' optical trigger.

Third, a more experimental method. You drill holes, but instead of photodiodes, you insert a insulated electrode with one non-insulated point in the middle. Then, apply a low-current high-voltage across. When the projectile passes, the voltage will jump through it and trigger something. I know you think, why not apply the voltage directly from the capacitor, not needing triggering circuits? Well, because: You would need very sturdy electrodes and make them easy to replace. They will burn out and weld scraps on the projectile making it slide less good in the barrel and not usable another shot. You would probably need to adjust the electrodes after some time due to burn-out. The nice noise-less coilgun will be a big bang shower of sparks. The you could instead buy a firearm. And you would need high-voltages, so high that arcing can occur, since the projectile does not fill 100% of the barrel since it slides inside. Well, let's return to using high-voltage gaps inside barrel just as triggers, not switches. The high-voltage from perhaps a small disc cap could trigger a big external spark-gap. Difficult, but possible. Remember, the high-voltage shall not enter any sensitive circuits, and definiately not the coil-capacitor you want to trigger. Burning holes inside it with high-voltage could be fatal to it. In this design, a metal barrel is also quite not advisable unless it is totally insulated from the coils. The enammeled coilwire might be punched holes in, if there is high enough voltage in the barrel.

Forth, the timed trigger. If you use the exact same projectile every time, the exact same voltage in capacitors and so on, you could just apply pulses from a PC working as a timer. You could fine-tune this to good performance, but the moment when your projectile has been shot away, the timing will probably be wrong, since the parameters aren't the same as when set. Since it includes precise timing and programming probably in a sensitive microcontroller, it isn't even easy to do. I can't find one single good reason to do this.

After you know your choice triggers, you need to trigger your switch. And this can't usually be done directly from the sensor. You need to filter or amplify, probably sharpen the pulse, giving the switch a high-current sharp pulse to trigger presicely. To do this, the most easy thing is to use is a driver IC. They are usually as far as we need to know one-stage logical gates, usually inverters, since they are the easyest to make. But instead of that small 20mA or whatever normal gates deliver, it is designed to supply over 1 amperes of current. The are otherwise known as MOSFET drivers. The small capacitance which must be filled up before the MOSFET conducts fully, is very fast taken care of. Why is this important? Because, when the MOSFET conducts only half, it has a double resistance and this resistance generates heat. If it stayes to long in this state due to low current triggering, it might burn out. The MOSFET driver is also used to trigger thyristors and transistors, but you would have to modify some to prevent the driver to burn out. As said, it can supply much current, but only for a very short time. Continous current from it, as the thyristor and transistor will draw, will over time burn it out. It is only made to supply short pulses.

|

|

www.coilgun.ru |